Project Rupshi

Updated on October 15, 2025

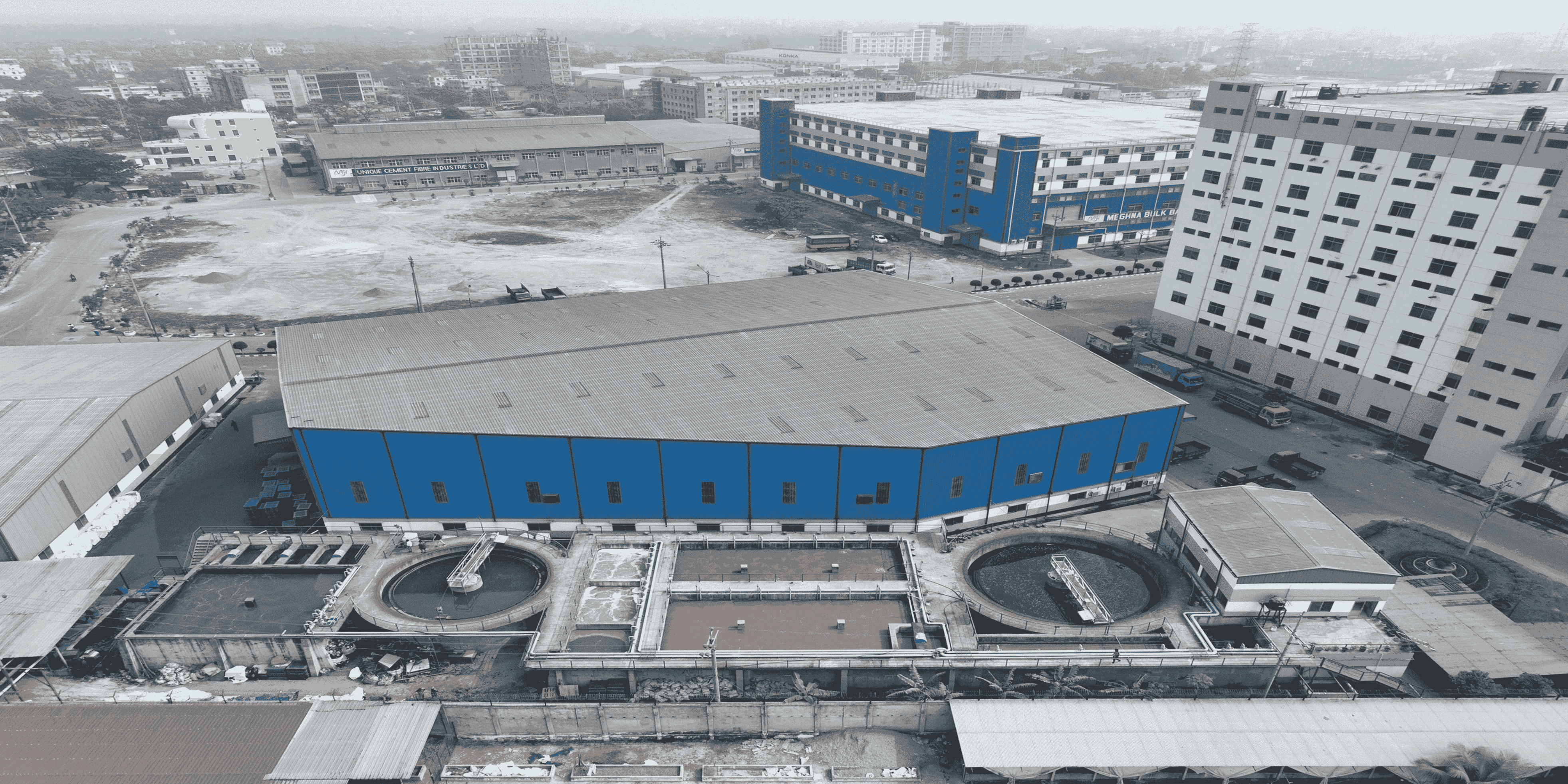

Water Technology BD Ltd. Successfully Delivers Comprehensive ETP Solutions for City Economic Zone (Rupshi).

We are proud to announce the successful completion of a landmark project, demonstrating our commitment to advanced waste water management and environmental sustainability across critical industrial sectors. This multifaceted initiative involved the design, implementation, and commissioning of four distinct Effluent Treatment Plants (ETPs), providing tailored solutions for a prominent food conglomerate, an edible oil refinery, a sugar refinery, and an auto rice mill. This project highlights our ability to address diverse and complex industrial wastewater challenges, ensuring stringent environmental compliance and promoting sustainable operations.

Central ETP for Dekko Foods: Mastering Diverse Effluents

A cornerstone of this project was the development of a sophisticated Central ETP for Dekko Foods, a leading name in the food industry. This facility was engineered to manage the varied and high-volume wastewater streams originating from their diverse operations, including confectionery and various dairy product manufacturing units. The challenge lay in treating a complex mix of organic loads, fats, oils, greases, and fluctuating pH levels inherent to mixed food processing. Our comprehensive solution now ensures that DekKo Foods' operations meet and exceed environmental discharge standards, supporting their commitment to responsible food production.

Capacity: This central ETP is designed to treat approximately [Central ETP Capacity] of wastewater daily.

Specialized ETP for Edible Oil Refinery: Tackling FOG and Organics

For a major edible oil refinery, we deployed a specialized ETP engineered to address the distinct challenges of their effluent. Edible oil refining wastewater is notably characterized by high concentrations of fats, oils, and greases (FOG), along with significant organic loads. Our robust treatment system effectively mitigates these pollutants, preventing environmental contamination and ensuring the refinery's operations align with the highest sustainability benchmarks.

Capacity: The edible oil refinery ETP has a treatment capacity of approximately [Edible Oil ETP Capacity] per day.

Dedicated ETP for Sugar Refinery: Managing High Organic Content

The sugar refining industry presents its own set of wastewater complexities, primarily due to high organic content, color, and fluctuating flow characteristics. Our dedicated ETP for a leading sugar refinery was designed to efficiently process these challenging waste streams. The implemented solution effectively reduces biochemical and chemical oxygen demand, removes problematic color, and ensures the treated water meets regulatory requirements, contributing to the refinery's environmental stewardship.

Capacity: This advanced ETP manages approximately [Sugar Refinery ETP Capacity] of wastewater daily.

Tailored ETP for Auto Rice Mill: Addressing Solids and Odor

Finally, for an auto rice mill, we delivered an ETP specifically tailored to handle the unique wastewater profile of rice processing. This includes high levels of suspended solids, organic matter from starch and bran, and potential odor issues, particularly from parboiling operations. Our system effectively separates solids, reduces organic load, and controls odors, enabling the mill to operate cleanly and sustainably within its community.

Capacity: The auto rice mill ETP treats approximately 2400 m³ of wastewater per day.

A Commitment to Sustainable Industrial Growth

This multi-project success highlights WTBL's expertise in providing customized, high-performance wastewater treatment solutions across a spectrum of industries. By leveraging advanced methodologies and a deep understanding of industry-specific challenges, we empower our clients to achieve environmental compliance, enhance operational efficiency, and contribute to a healthier planet. We remain dedicated to pioneering sustainable practices and supporting industrial growth that prioritizes ecological responsibility.

We are proud to announce the successful completion of a landmark project, demonstrating our commitment to advanced waste water management and environmental sustainability across critical industrial sectors. This multifaceted initiative involved the design, implementation, and commissioning of four distinct Effluent Treatment Plants (ETPs), providing tailored solutions for a prominent food conglomerate, an edible oil refinery, a sugar refinery, and an auto rice mill. This project highlights our ability to address diverse and complex industrial wastewater challenges, ensuring stringent environmental compliance and promoting sustainable operations.

Central ETP for Dekko Foods: Mastering Diverse Effluents

A cornerstone of this project was the development of a sophisticated Central ETP for Dekko Foods, a leading name in the food industry. This facility was engineered to manage the varied and high-volume wastewater streams originating from their diverse operations, including confectionery and various dairy product manufacturing units. The challenge lay in treating a complex mix of organic loads, fats, oils, greases, and fluctuating pH levels inherent to mixed food processing. Our comprehensive solution now ensures that DekKo Foods' operations meet and exceed environmental discharge standards, supporting their commitment to responsible food production.

Capacity: This central ETP is designed to treat approximately [Central ETP Capacity] of wastewater daily.

Specialized ETP for Edible Oil Refinery: Tackling FOG and Organics

For a major edible oil refinery, we deployed a specialized ETP engineered to address the distinct challenges of their effluent. Edible oil refining wastewater is notably characterized by high concentrations of fats, oils, and greases (FOG), along with significant organic loads. Our robust treatment system effectively mitigates these pollutants, preventing environmental contamination and ensuring the refinery's operations align with the highest sustainability benchmarks.

Capacity: The edible oil refinery ETP has a treatment capacity of approximately [Edible Oil ETP Capacity] per day.

Dedicated ETP for Sugar Refinery: Managing High Organic Content

The sugar refining industry presents its own set of wastewater complexities, primarily due to high organic content, color, and fluctuating flow characteristics. Our dedicated ETP for a leading sugar refinery was designed to efficiently process these challenging waste streams. The implemented solution effectively reduces biochemical and chemical oxygen demand, removes problematic color, and ensures the treated water meets regulatory requirements, contributing to the refinery's environmental stewardship.

Capacity: This advanced ETP manages approximately [Sugar Refinery ETP Capacity] of wastewater daily.

Tailored ETP for Auto Rice Mill: Addressing Solids and Odor

Finally, for an auto rice mill, we delivered an ETP specifically tailored to handle the unique wastewater profile of rice processing. This includes high levels of suspended solids, organic matter from starch and bran, and potential odor issues, particularly from parboiling operations. Our system effectively separates solids, reduces organic load, and controls odors, enabling the mill to operate cleanly and sustainably within its community.

Capacity: The auto rice mill ETP treats approximately 2400 m³ of wastewater per day.

A Commitment to Sustainable Industrial Growth

This multi-project success highlights WTBL's expertise in providing customized, high-performance wastewater treatment solutions across a spectrum of industries. By leveraging advanced methodologies and a deep understanding of industry-specific challenges, we empower our clients to achieve environmental compliance, enhance operational efficiency, and contribute to a healthier planet. We remain dedicated to pioneering sustainable practices and supporting industrial growth that prioritizes ecological responsibility.